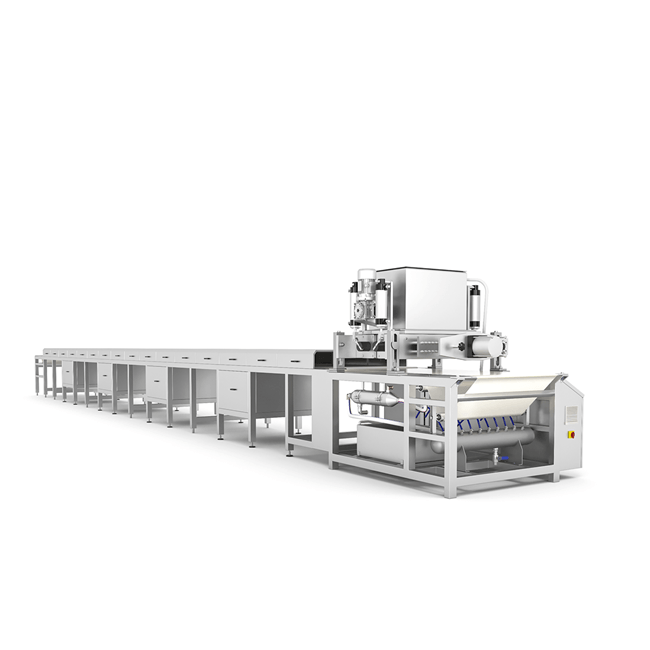

Our chocolate belt coating machine has excellent performance for coating chocolate on various products, like peanuts, almonds and dry fruits, etc. Not only can it be applied to chocolate coating, but also powder coating, which means spray powdered flavoring agent on peanuts. The whole belt coating machine is made by 304 SS which conforms to food safety and hygiene. It’s controlled by PLC, so the operator can set and save different formula and recipes in it. There are eight sprayers inside our belt coating machine. They will guarantee the products have a even and smooth coating.

Since it will work with chocolate mass feeding system, it will help customer to save labor cost and improve capacity. The belt not only moves forward, but also moves backward too, so operators do not need to touch the products from feeding to discharging which guarantee the food safety and hygiene during production. Depends on different products, the output will be 200kg-300kg/h. No matter what you want to make are dragee, snacks or confectionery, you will be satisfied with our belt coating machine.