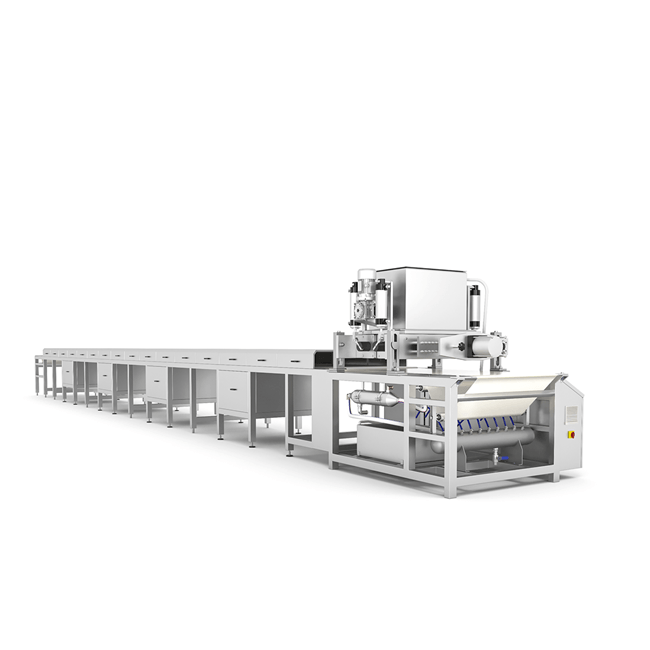

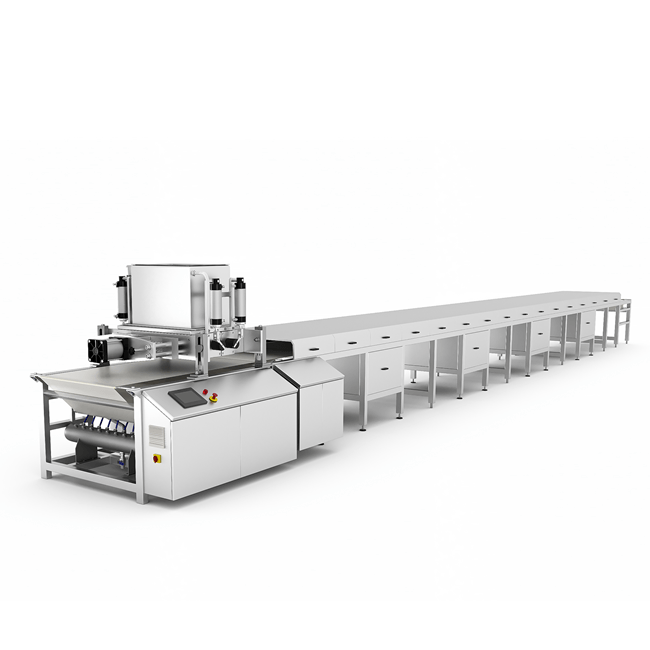

Our chocolate chips line applies to not only chocolate, but also cocoa mass too, so this line is suitable for both of chocolate manufacturers and cocoa beans processors. We have 600MM to 2000MM chocolate chips line for customers choice. No matter what they need is 50kg/h or 500kg/h, we can supply for proper chocolate chips line for them.

Chocolate chips, drops and buttons are used in B2B business mainly, so they will be melted again when they arrive client’s workshop. Compared with 500g or 1Kg blocks, it takes shorter time to melt these chips, drops and buttons. So it’s more flexible and convenient to small and medium manufacturers. Our chocolate chips line can make 0.08g-0.1g chips (10,000-12,000 pcs/kg), which means it can be put on cookies and bars to improve the flavors and appearance.