Chocolate Mass Processing

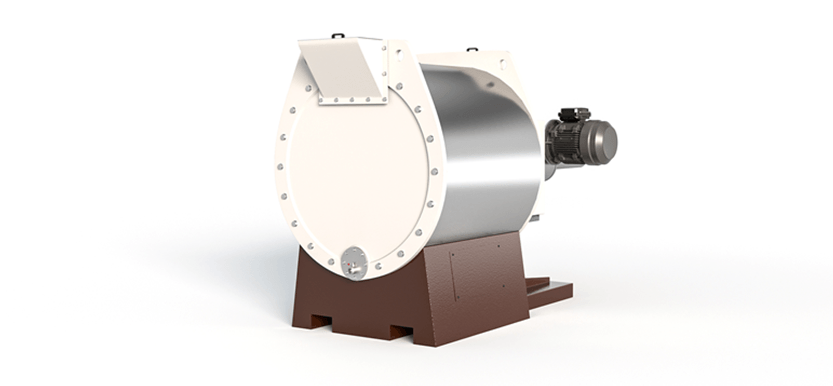

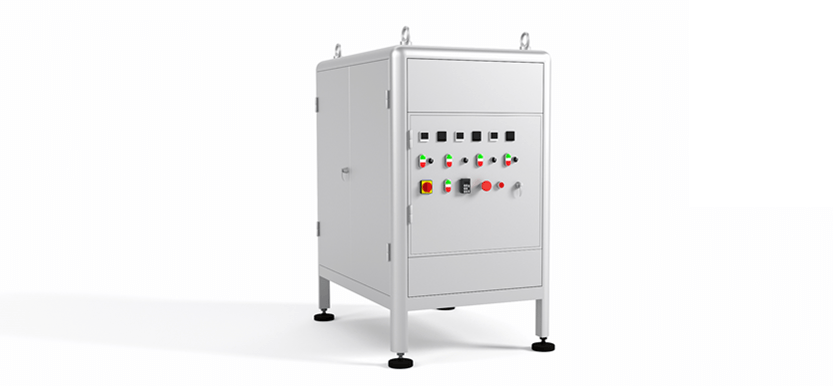

According to the final product, output, workshop space and budget provided by the customer, we can supply semi-automatic and fully automatic chocolate mass processing equipment. Our chocolate mass processing equipment includes sugar pulverizer, fat melting tank, chocolate conche refiner, chocolate ball mill and chocolate conching machine. Chocolate conche refiner and chocolate ball mill are necessary chocolate mass production equipment in chocolate industry. Our chocolate conche refiner integrates mixing, grinding and refining, which is suitable for customers with small and medium output and low investment. The ball mill has large output and high grinding efficiency, which is suitable for customers with medium and large output. Our chocolate mass processing equipment is widely used in the production of chocolate mass, chocolate spread and cocoa mass due to their stable performance and reliable quality. The final products are not only used in the production of chocolate, but also in the production of bakery products and confectionery.

Learn More >