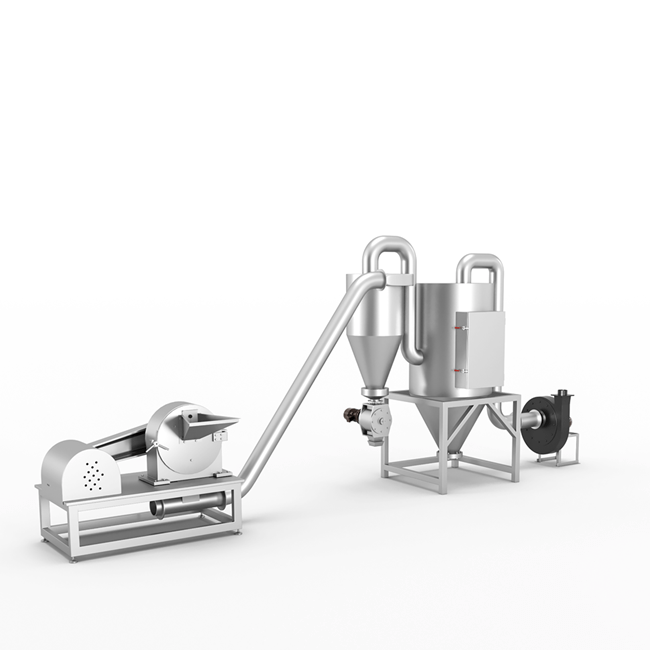

The principle of our sugar grinding machine is making use of the high-speed relative movement of the movable hammers and the fixed tooth ring to crush the sugar through the comprehensive effect of striking and friction of the tooth ring. Thanks to our technician and engineers team, the powder residual issue is improved greatly, because of processing of the inner surface of the enclosure. As a result, the production of sugar powder can better conform to the state standard and the GMP requirement.

We have 100-300kg/h, 100-500kg/h and maximum 100-1000kg/h sugar pulverizer for option, depending on customer’s demand on capacity. For small and medium capacity, the crushed sugar powder can be collected and stored directly through mesh screen.

However, for big capacity, the crushed sugar powder flows into the cyclone separator by the gravitation of blower and rotating centrifugal force, then feeds through gate blower, dust come into the pulse dust-evacuator box, filtrated and recycled by the filter cylinder. This production process will bring refined sugar podwer, improve operation safety and avoid the dangerous situation.