What types of chocolate can the 1200MM Popcorn Decorating Line handle?

The machine is designed to handle both dark and white chocolate, with precision decorating capabilities. If needed, it can also be adapted to handle other chocolate varieties upon request.

Can this machine be integrated with other Harmo chocolate processing equipment?

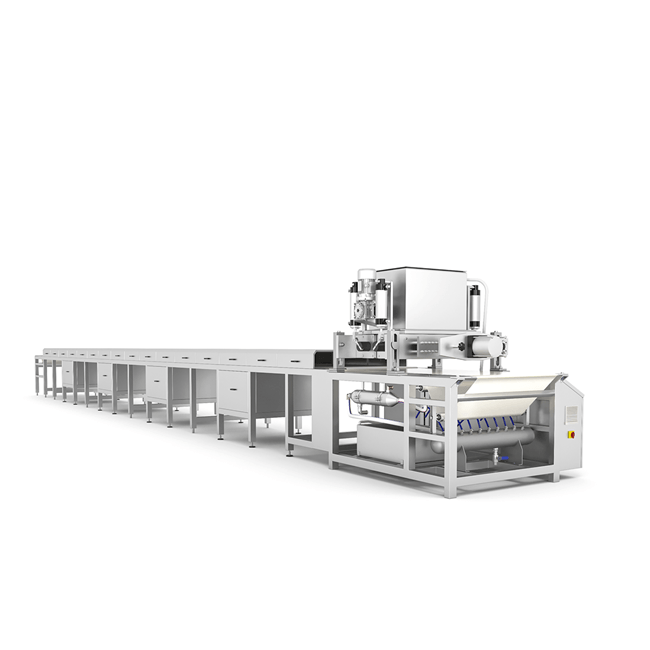

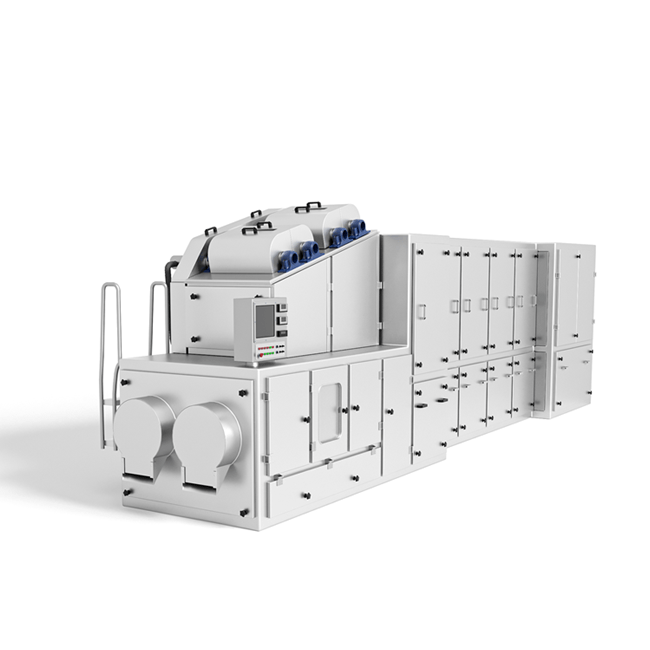

Yes. One of its biggest advantages is its shared cooling tunnel design, which allows seamless integration with other Harmo machines such as chocolate enrobers, cluster extruders, chips depositors, and one-shot depositors. This makes it ideal for building a modular and scalable production line.

What is the maximum production capacity of the line?

The exact production capacity depends on your specific configuration and throughput speed. Suzhou Harmo customizes the system based on your factory layout and production goals, so we encourage you to contact us for tailored solutions.

Can the cooling tunnel be customized in length and function?

Absolutely. The cooling tunnel is modular, and its length can be adjusted to fit your factory space and production needs. It can also be shared among different chocolate lines, enhancing efficiency.

Is the machine easy to clean and maintain?

Yes, the 1200MM Popcorn Decorating Line is made with food-grade stainless steel (SUS304) and designed with easy-access panels and CIP (clean-in-place) options. Routine maintenance is straightforward, and we provide full documentation and support.

Do you provide installation and training services?

Yes. Suzhou Harmo Food Machinery offers on-site installation, commissioning, and operator training to ensure smooth startup and long-term operation. We also offer remote support for international clients.